De-tails

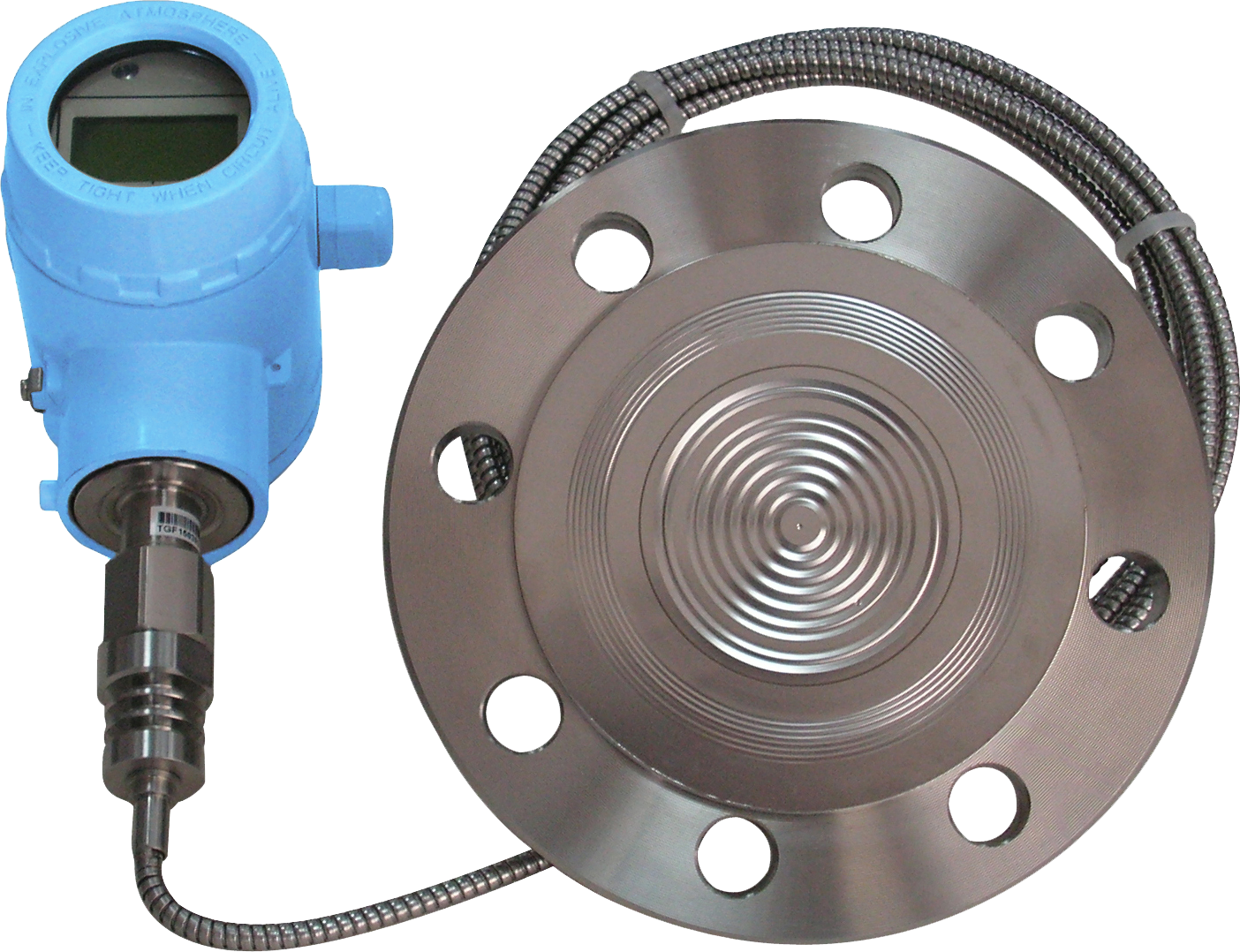

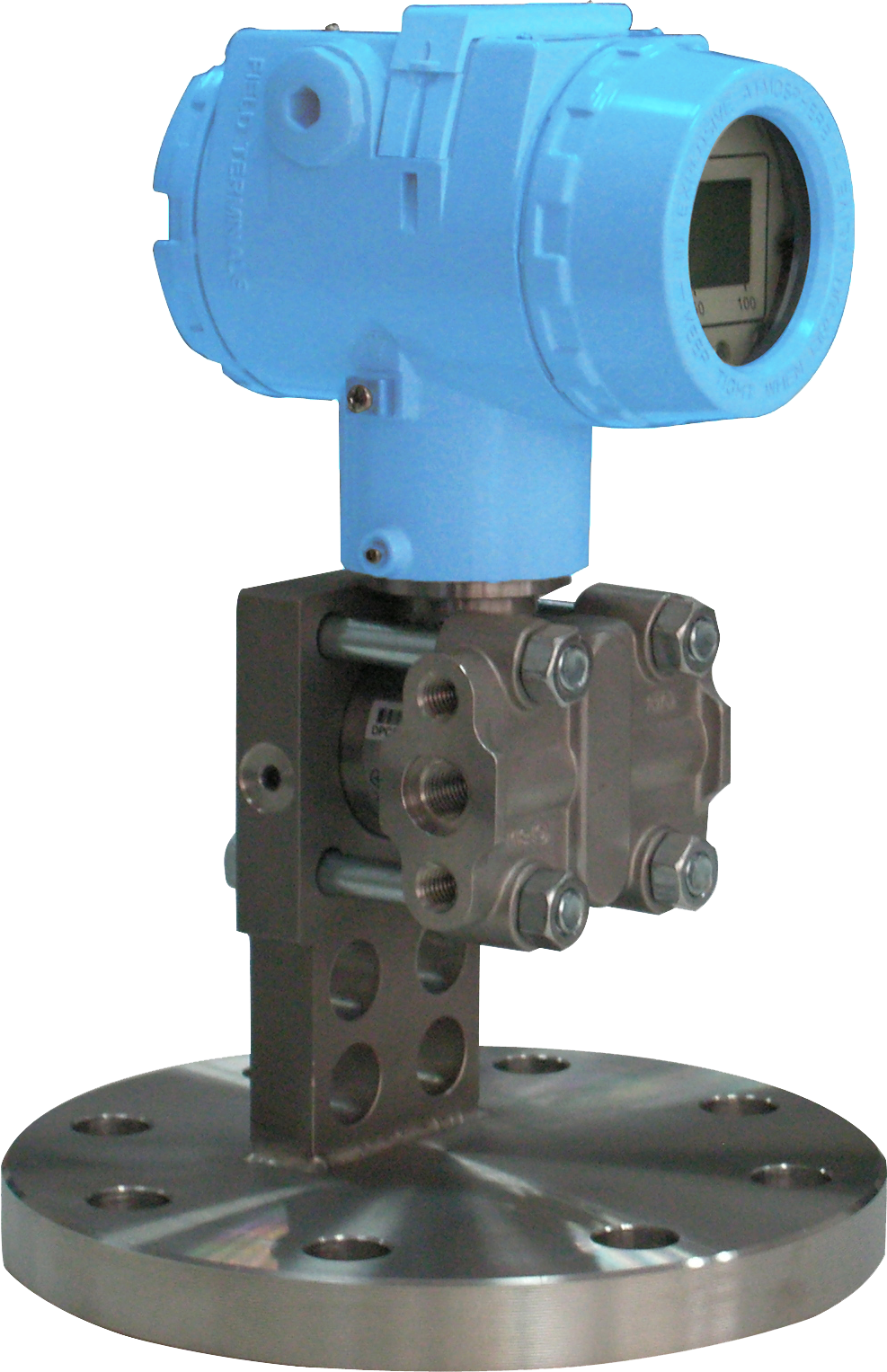

PT611-CA remote pressure, absolute pressure transmitter used in the process of industrial production pressure (gaugepressure), absolute pressure measurement (such as the measured medlium with high viscosity, corrosive, polymerizationtendency or high temperature pressure, absolute pressure measurement conditions), It has output signals in line with4mA~20mA/HART, PROFIBUS-PA and FF protocols. Digital signals contain a variety of configurations, signal status and faultself-dliagnosis information. Optional LCD head is used to display process pressure, signal status and fault self-dliagnosisinformation.

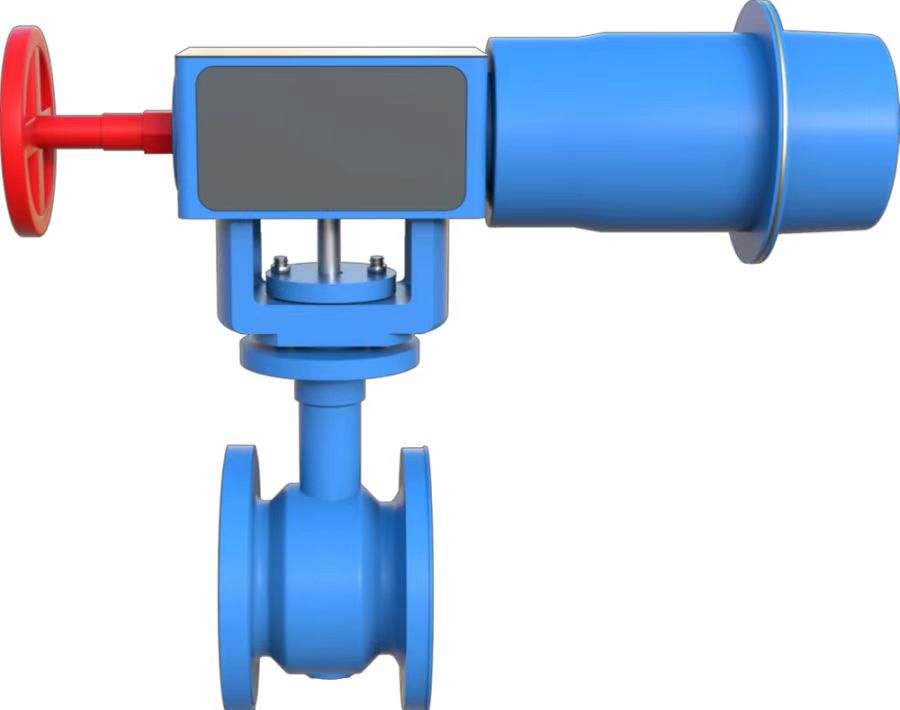

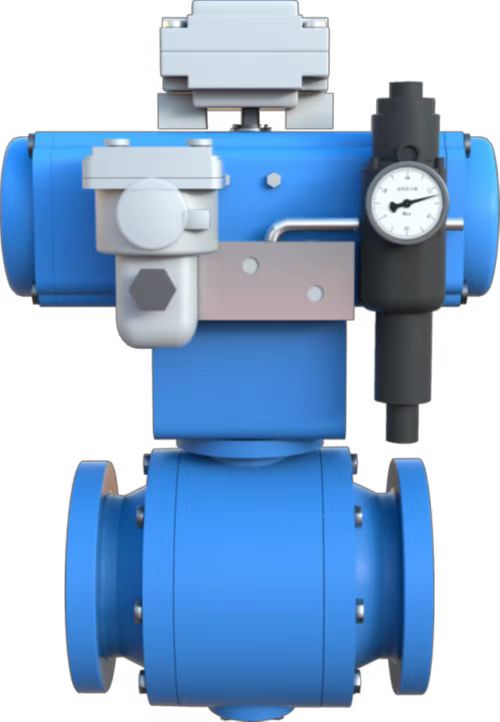

PT611-CA remote pressure and absolute pressure transmitter structure is composed of PT611-CA pressure, absolutepressure transmitter and remote pressure sealing device , its working principle is the same as that of PT611-CA pressure andabsolute pressure transmitter, only the process pressure transfer path is slightly different: The isolation diaphragm on theremote sealing device and its filing liquid isolate the process medium and measuring sensor.The process pressure firstpasses through the isolation diaphragm and filing liquid on the remote sealing device, then through the isolation diaphragmand filling liquid on the transmitter body, and finally reaches the measuring sensor.

PT611-CA remote transmission pressure transmitter range (standard product) is 6kPa~40MPa,PT611-CA remotetransmission absolute pressure transmitter range (standard product) is 4OkPa abs.~3MPa abs.Remote transmission flangeconforms to ANSl or DiN standards. The connection forms are flat flange type, insert cylinder type, clamp type, fiange mount-ing type, thread mounting type, camp type, coupling type, micro, etc. The pressure rating is Class 150 lb, Class 30o lb, Class600 lb,1.6MPa/4MPa,6.4MPa or 10MPa, etc. The isolation diaphragm on the remote transmission flange is made of 316Lstainless steel, Hastelloy C, tantalum,PFA coating,F46 fim coating, gold plating, etc., which can meet the pressure and abso-lute pressure measurement requirements under special conditions in different industrial production processes.