De-tails

PT611-BA liquid level transmitter is used for the measurement of (dfferential pressure) liquid level in the process ofindustrial production (such as the measured medium with high viscosity, corrosion, pclymerization tendency or high tempera-ture differential pressure liquid level measurement conditions), with 4mA-20mA/HART, PROFIBUS-PA, FF protocol outputsignal, The digital signal contains a varity of configuration, signal state and fault sell-diagnosis information.The optional LCDwatch head is used to display process pressure, signal state and fault sel-diagnosis information. The local button can com-plete the adjustment of the zero full and other configuration functions.

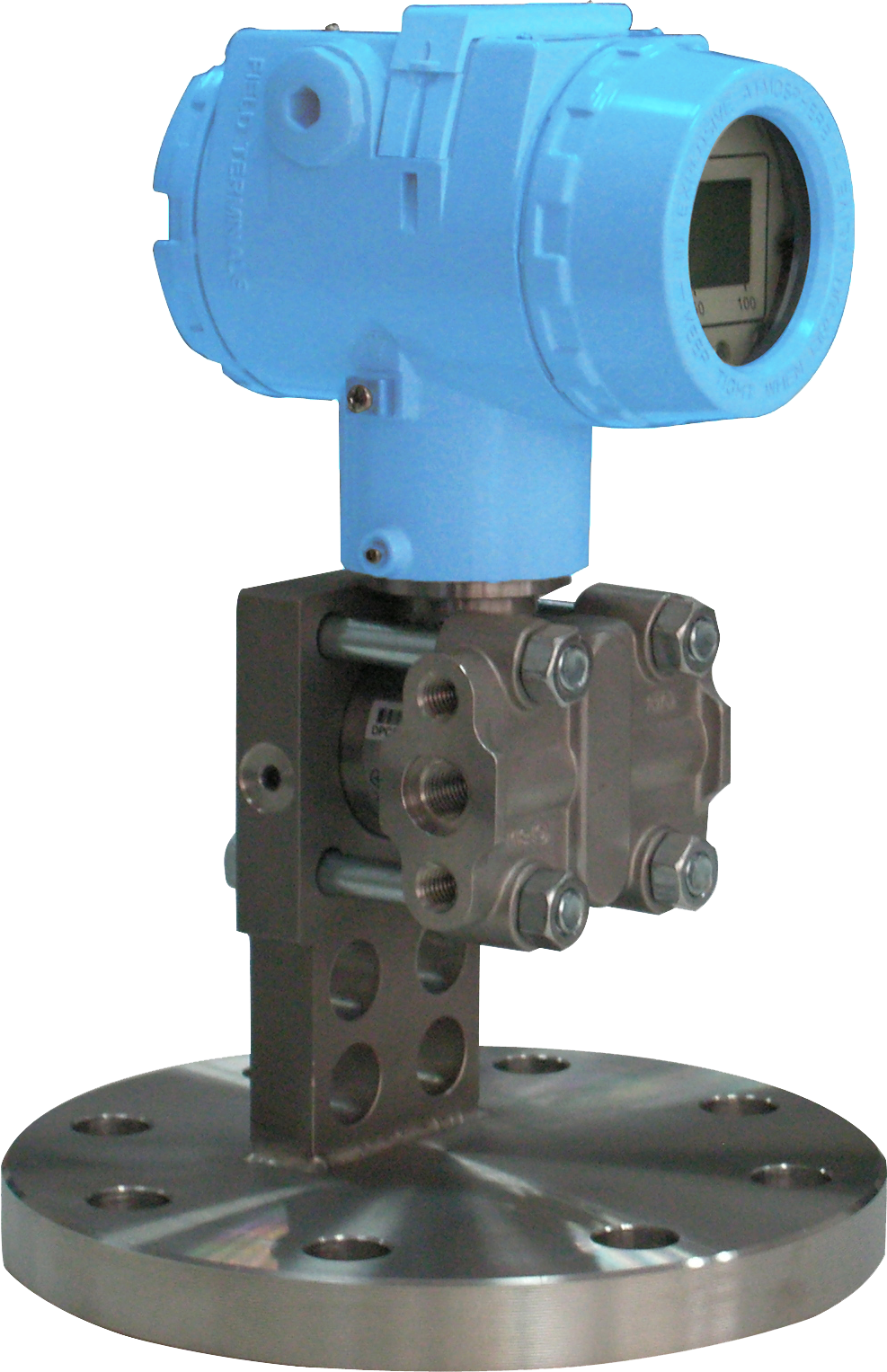

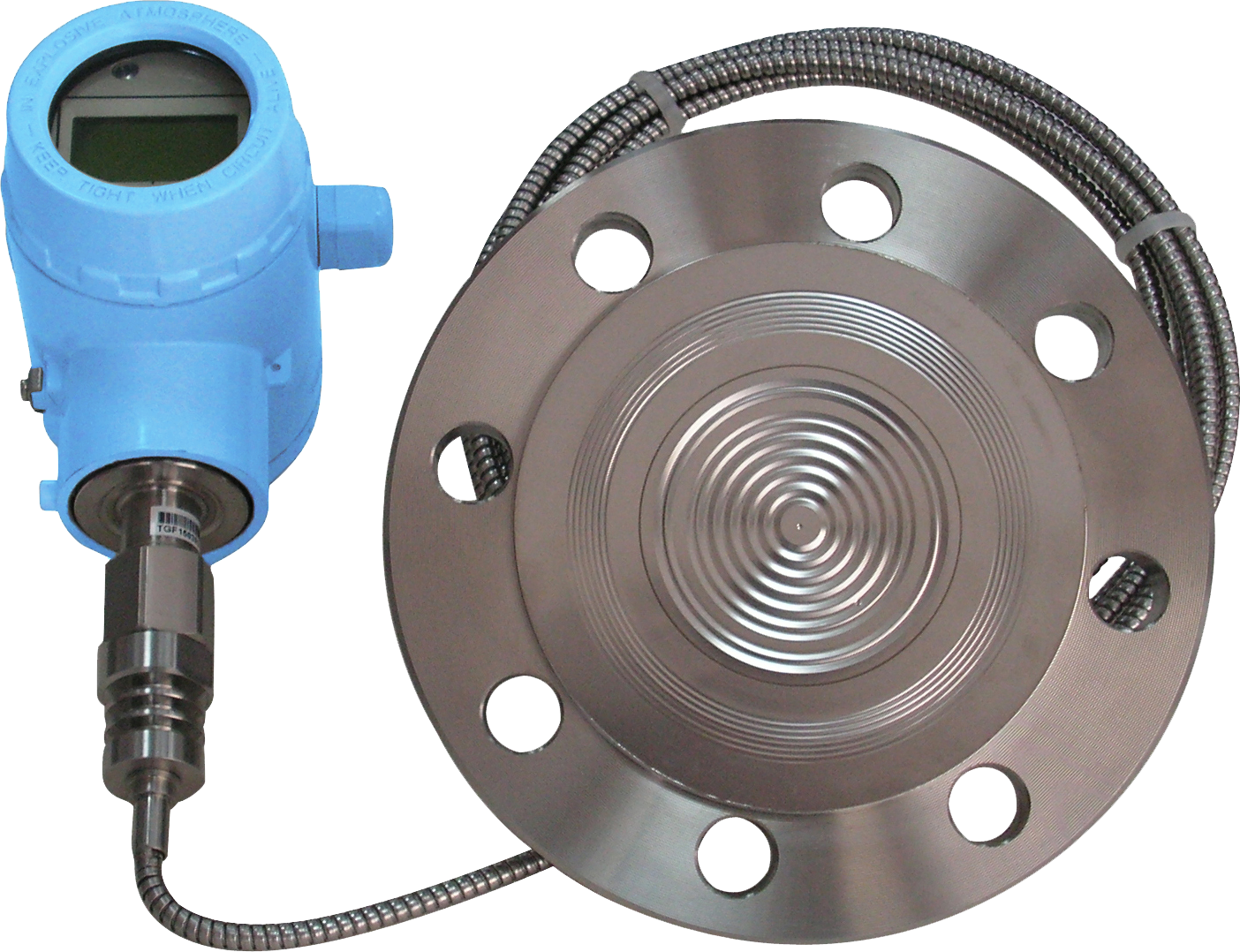

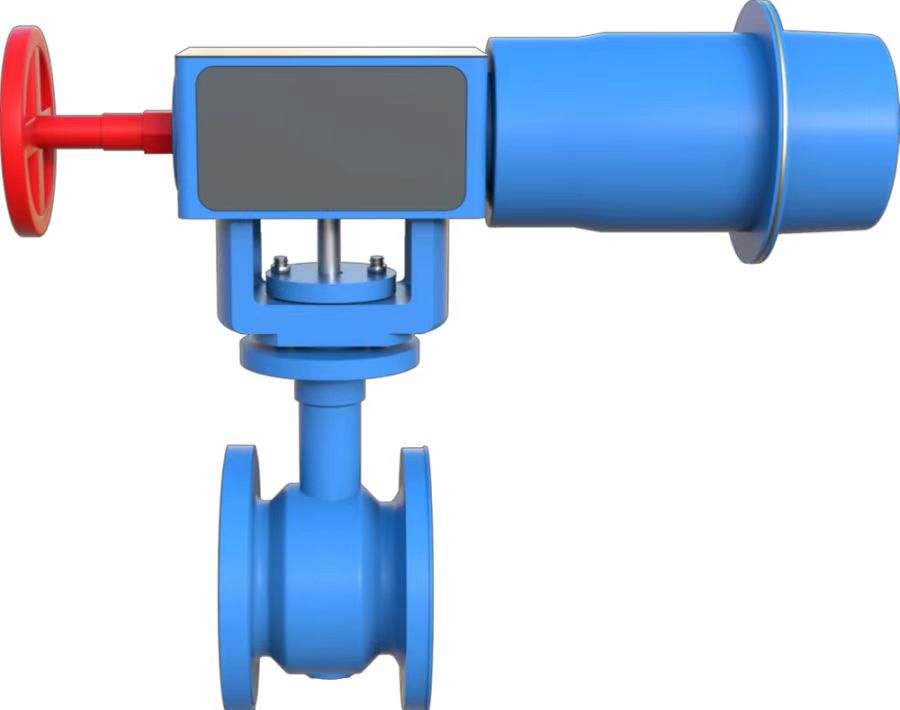

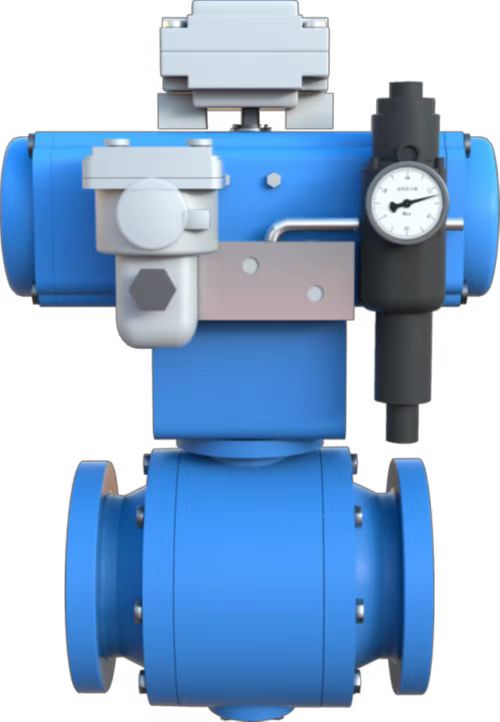

PT611-BA liquid level transmitter structure is composed of PT717-BA differential pressure transmitter and liquid levelflange, its working principle is the same as that of PT717-BA differential pressure transmitter, only the high pressure sidepressure transfer path is slightly different:The isolation diaphragm on the liquid level flange and its illing liquid isolate theprocess medium and the measuring sensor.The pressure on the high pressure side first passes through the isolationdiaphragm and illing liquid on the liquid levelflange, then passes through the isolation diaphragm and illing liquid on the trans-mitter body, and finally reaches the high pressure side of the measuring sensor.

PT611-BA liquid level transmitter range (standard product) is 4kPa~1MPa, level flange in line with ANSl or DIN standards,connection forms are flat flange type and insert cylinder type, etc. The pressure rating is Class 150 lb, Class 30o b, Class 6O0lb,1.6MPa/4MPa,6.4MPa or 10MPa. The isolation diaphragm on the liquid level flange is made of 316L stainless steel,Hastelloy C, tantalum, PFA coating, F46 film coating, gold plating, etc. It can meet the requirements of measuring differentialpressure level in different industrial processes.