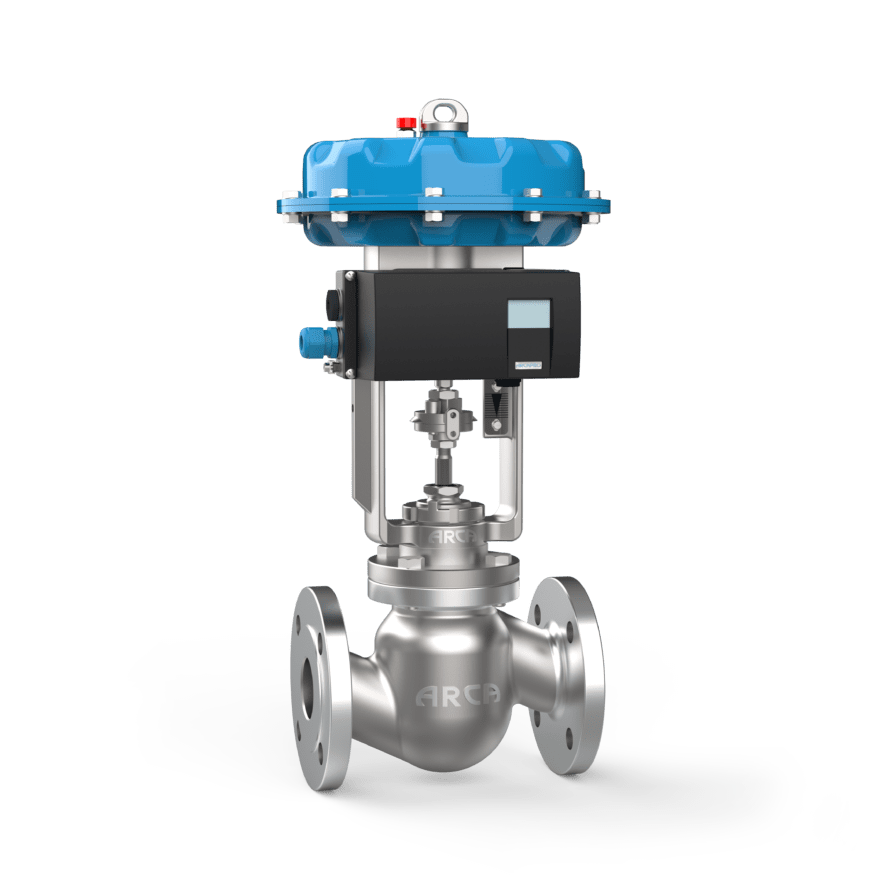

ECOTROLO TRIMS111111

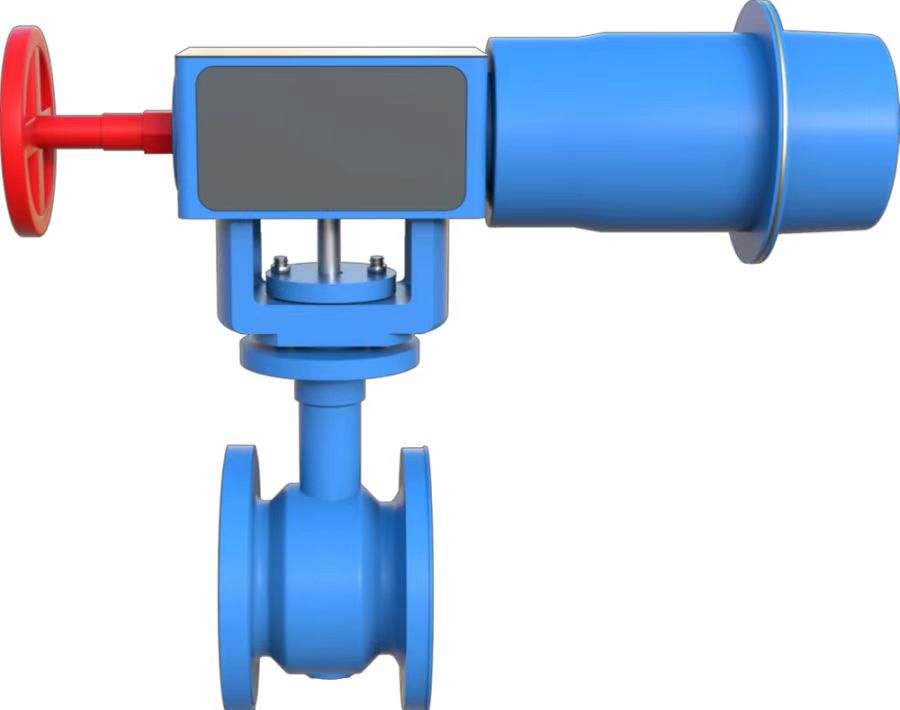

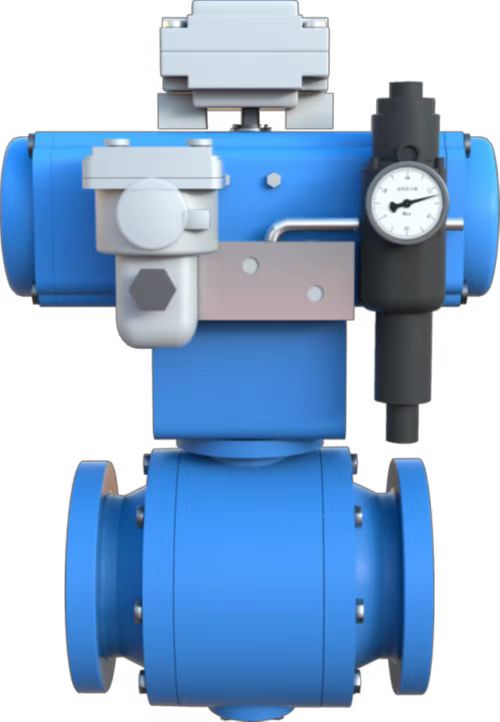

Standard parabolic plug

For laminar or turbulent flow, the single-stage, dirt-resistant parabolic plug is the best choice. In the case of globe control valves without pressure balancing and up to nominal size DN 100 (4″), the plug and stem are one-piece; for higher sizes, the design is two-part. As standard, the characteristic curve of the parabolic plugs is adjustable; the standard characteristics curves are linear and equal percentage. The valve sealing is metallic type with Class IV leakage (Class V as an option). In order to counteract the cavitation-related erosion phenomena occurring under high pressure conditions, parabolic plugs (single or multi-stage) and clamping seat can also be made of highly wear-resistant ceramic materials. Noise emissions can be reduced with a low-noise perforated cage.